PRESS RELEASE

Natural Rubber Supply Chain comes together to build unique sustainability assurance benchmark

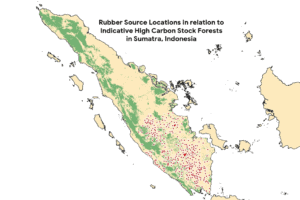

Singapore, 20 June 2024: Members of the Global Platform for Sustainable Natural Rubber (GPSNR), who represent almost 60% of the value chain, have agreed on an industry wide assurance system in an Extraordinary General Assembly held yesterday. Through this agreement, the natural rubber industry now has a standardized stage-by-stage process through which companies can commit to, implement and verify strong sustainability standards and practices in their operations.

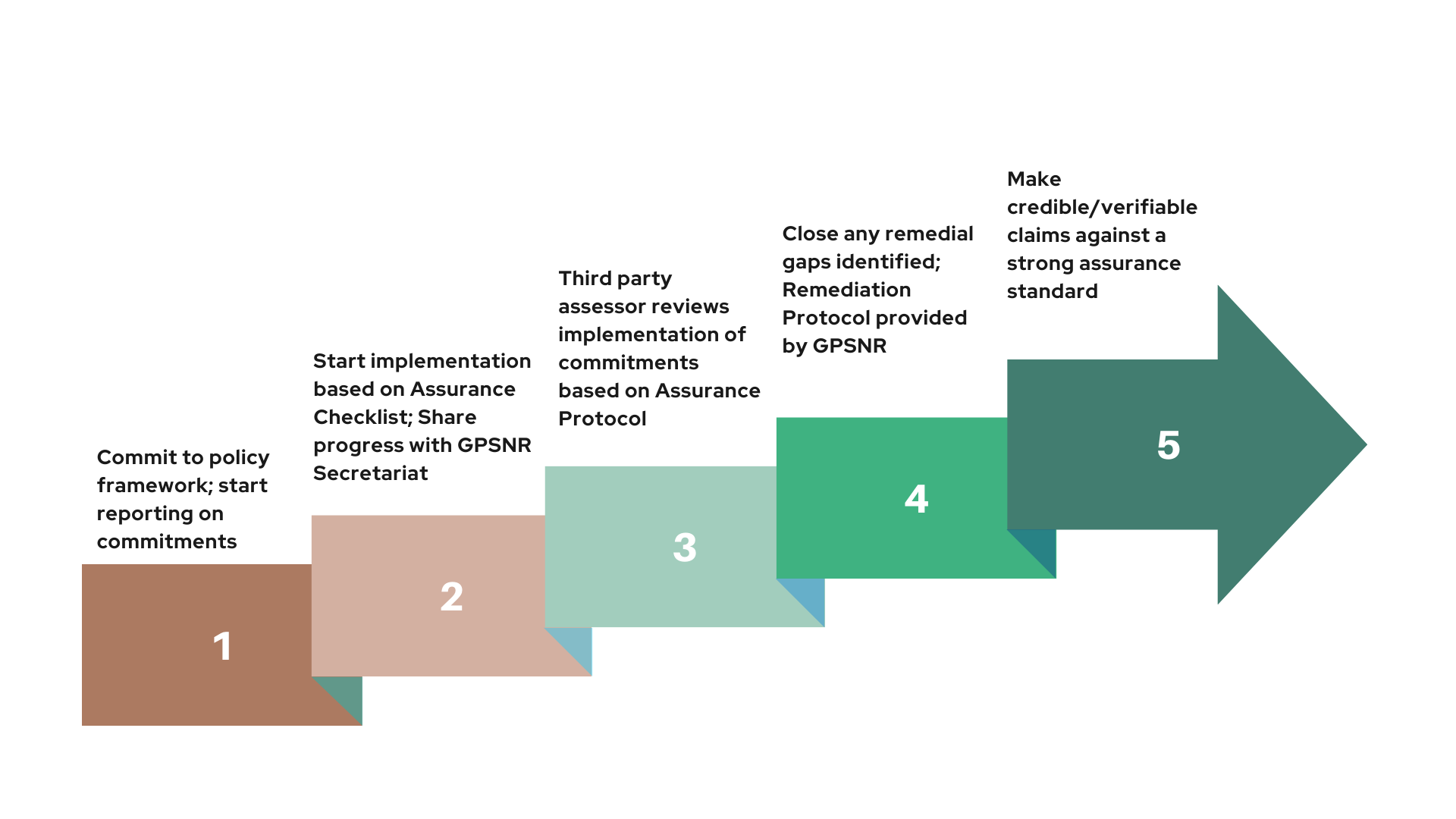

GPSNR members’ stage-by-stage progression towards verified sustainability assurance

The Assurance system is currently being piloted by some volunteer manufacturers and processors until August 2024. Concurrently, three of its four mandatory elements have also been put up on a public consultation to seek comments and additional inputs that will help finetune the different aspects of the model. The feedback collected via the pilots and the public consultation will be integrated into the assurance model and put up for members’ review at the Annual General Assembly in October 2024. By 2025, all GPSNR members will be using this model in their operations.

The model covers four mandatory elements – an Assurance Assessment checklist which will spell out the minimum requirements that members will have to meet on all aspects of the GPSNR policy framework, an Assurance Protocol which will provide guidelines to external assessors, a Remediation Protocol that includes actions and timelines to close the gaps identified by the assessors and a Members Journey or broad timeline to achieve these requirements. Additionally, the model also includes supplementary tools that will support members in putting the assurance model into practice, like a due diligence framework and national risk assessments, amongst others.

‘’Having a system that can verify and cross check the implementation of our members’ commitments has always been our overarching goal at GPSNR. With the voting in of the Assurance Model structure, our members have demonstrated their intent to deliver on their sustainability promises. I am especially proud of the multistakeholder nature in which the assurance model has been agreed on, keeping in mind the practical position of each member category.’’ said Stefano Savi, GPSNR’s Platform Director.

GPSNR’s membership is meeting next week in Singapore to iron out the details of the minimum requirements spelt out in the Assurance Model checklist, the nature of the claims that can be made, the feedback from the pilots and the assurance protocol for third party assessors.

END

About GPSNR:

GPSNR is an international membership driven platform set up to define sustainability for the natural rubber value chain. It brings together various stakeholders to a common ground based on fairness, equity and environmental sustainability. More on sustainablenaturalrubber.org

For more information, please contact:

Bani Bains

Communications Manager

Email: bani.bains@gpsnr.org

Ph: +65 97268165